MechaBits KraftWerk'r

Posted by MechaBits

|

MechaBits KraftWerk'r October 04, 2016 05:09PM |

Registered: 8 years ago Posts: 1,671 |

in 2017 the Robots (Kraftwerk) are coming to Liverpool for a 3D showing of their amazing concert,

in celebration of getting my tickets I put together a new 3D Print Robot(for less money than the tickets for the concert),

more pics [io-matter.blogspot.co.uk]

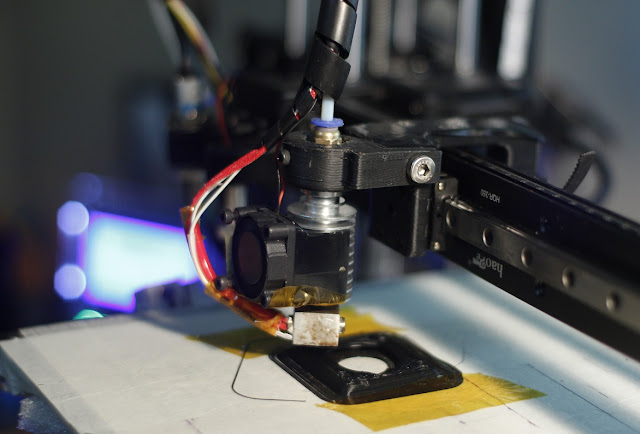

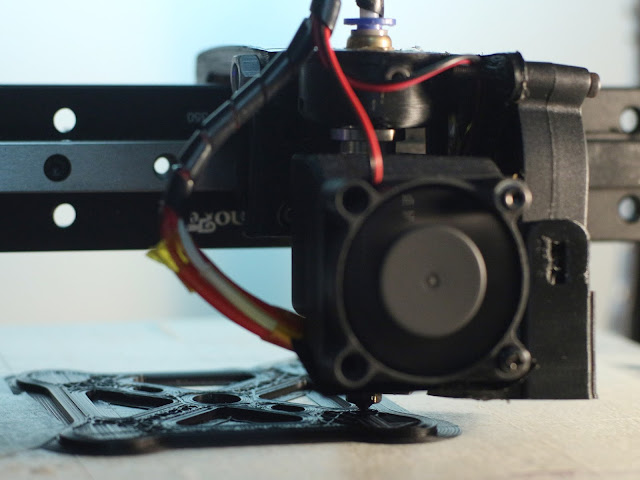

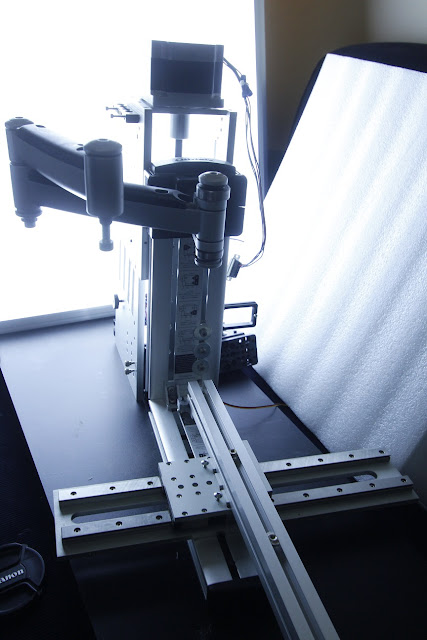

as I tried to minimize things, the one thing that has been the hardest on all of the 3D printers was having a simple arrangement for the bed, one I could move around and re-use, I had 3 pieces of 3030 left over from the cube, (BorgBoxBot) I had already made the bed from one piece, I had to take off the rail from another prototype, which is now(could be) a Z actuator for the cube, The new bed design was put together with a piece of 3030, a linear rail and a HD Caddy...then a couple of days later I thought what do I do with the other 2 pieces of 3030...and over the next couple of days trying to use up my silver excelevan on profile parts, I started to assemble the X and Z axis to compliment the other Y. I have 2x 6mm rods salvaged from a copy machine they are very stiff and just right length, so I made the first revision of the carriage, still waiting on the 6mm bearings, and I will probably incorporate more in final design.

The whole X Arm weighs 500g, including Z carriage.

The Arm can be mounted either way H or V, the Z does its job, but rather than print a revised part(my little raised guides where not in-line with the slots, so removed them with a razor), I printed another part to make the first part work better as there was a 2mm gap so bearing didnt sit right, which is a bearing spacer/ track anchor...without the track anchor the arm tilts up when moving down the Z which could actually be a good thing helping the hotend clear part. Perhaps a Special-K version of the carriage instead of a V shape, also want to try having one of the axle's adjustable..maybe a scissor action with springs?

a revision of the carriage will sort that out, I want to incorporate some leveling for the arm, and maybe an extra set of rollers that position can be adjusted, if I move the Z motor to the top then I dont need the printed bearing holder as the bearing will just sit on the frame easier to adjust, but I can use the bearing holder as a 12mm rod support so no waste there.

The base will probably not be in the cross arrangement, as I only have 2x 3030, and it would be a pain unless I had some short offcuts. I have a steel platter/stand from an old computer that the 3030 sits right on, but I am torn because the platter could also be used for the BorgBox...I did have 2 of those old computers but one was throw out before a use was found for it

Some build pics on the facebook page

Edited 7 time(s). Last edit at 10/04/2016 11:17PM by MechaBits.

|

Re: MechaBits KraftWerk'r October 08, 2016 02:36AM |

Registered: 8 years ago Posts: 1,671 |

Just a few more parts needed, I could go the perspex route for the carriage, might have a go at designing the sheet metal parts combine arm mount with Z carriage...if I wanted carbon fiber plates, the machine would probably end up more like other printers out there, if I print another carriage i'll possibly rearrange the Z lead, the anchor is working too well, I'll just use the slots on the carriage, and add a little ptfe, if I pick up another linear rail I'll probably upgrade it. Just received my 3030 m3 nuts so will replace the printed plastic ones holding the bed rail down while waiting for the postman.

Printing the joiners for the profile

Edited 2 time(s). Last edit at 10/09/2016 07:42AM by MechaBits.

|

Re: MechaBits KraftWerk'r October 17, 2016 04:17AM |

Registered: 8 years ago Posts: 601 |

|

Re: MechaBits KraftWerk'r October 17, 2016 07:53AM |

Registered: 8 years ago Posts: 120 |

|

Re: MechaBits KraftWerk'r October 17, 2016 09:02AM |

Registered: 8 years ago Posts: 1,671 |

yup your right x is the weakest link, you'd think i'd learn something from first design, 2 rods for X can work, but can also be made better with some bracing, a nd perhaps even better with redesign, I have lots of these 6mm(which appear to be as stiff as the 8mm's and have various machined ends, with flats & circlip grooves) rods left over so could modify design to include more...

I have one beautiful stiff rod ;o ))

))

but its 14mm girth most girls would not be happy with it.... but for a man tinkering on his own, i'll find a use for it...

most girls would not be happy with it.... but for a man tinkering on his own, i'll find a use for it...

So cant get linear bearing for 14mm but maybe a bushing, maybe print one...I have some nito denko nitoflon ptfe tape...some ptfe tube, and some normal bearings, so might make another solution, and incorporate this other 10mm rod....which i'm waiting on bearings for along with the 6mm...but much of this work could be shelved if I get another linear rail.

I have the Core cube also on the go, but this was just a little divertido, something that would go together quick with minimal parts, most of which where lying around, begging me to make them into something more.

Just found a nice little system, wonder if the arrangement could offer an alternative setup to the normal core gantry.

[www.aliexpress.com]

obviously scaled down a hell of a lot,

Edited 3 time(s). Last edit at 10/17/2016 09:36AM by MechaBits.

I have one beautiful stiff rod ;o

))

))but its 14mm girth

most girls would not be happy with it.... but for a man tinkering on his own, i'll find a use for it...

most girls would not be happy with it.... but for a man tinkering on his own, i'll find a use for it...So cant get linear bearing for 14mm but maybe a bushing, maybe print one...I have some nito denko nitoflon ptfe tape...some ptfe tube, and some normal bearings, so might make another solution, and incorporate this other 10mm rod....which i'm waiting on bearings for along with the 6mm...but much of this work could be shelved if I get another linear rail.

I have the Core cube also on the go, but this was just a little divertido, something that would go together quick with minimal parts, most of which where lying around, begging me to make them into something more.

Just found a nice little system, wonder if the arrangement could offer an alternative setup to the normal core gantry.

[www.aliexpress.com]

obviously scaled down a hell of a lot,

Edited 3 time(s). Last edit at 10/17/2016 09:36AM by MechaBits.

|

Re: MechaBits KraftWerk'r October 17, 2016 10:53AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: MechaBits KraftWerk'r October 17, 2016 02:52PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: MechaBits KraftWerk'r October 19, 2016 08:44AM |

Registered: 8 years ago Posts: 1,671 |

Win tickets to see Yello at the Kraftwerk...

[www.udiscovermusic.com]

Can I be your +1

Hear the new album [www.youtube.com]

Edited 4 time(s). Last edit at 10/19/2016 08:56AM by MechaBits.

[www.udiscovermusic.com]

Can I be your +1

Hear the new album [www.youtube.com]

Edited 4 time(s). Last edit at 10/19/2016 08:56AM by MechaBits.

|

Re: MechaBits KraftWerk'r October 19, 2016 02:42PM |

Registered: 8 years ago Posts: 1,671 |

Cant mention Kraftwerk & Yello without a little nod to Numan, especially since he probably influenced the design of my first printer with this prophetic blueprint for the future of 3D printing geometry

Edited 1 time(s). Last edit at 10/19/2016 02:43PM by MechaBits.

Edited 1 time(s). Last edit at 10/19/2016 02:43PM by MechaBits.

|

Re: MechaBits KraftWerk'r October 19, 2016 03:22PM |

Registered: 11 years ago Posts: 5,780 |

Since we're talking music and 3D printing, check the lyrics to Tesselate by Alt J: [www.youtube.com]

"til morning comes, let's tesselate"

Edited 1 time(s). Last edit at 10/19/2016 03:22PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

"til morning comes, let's tesselate"

Edited 1 time(s). Last edit at 10/19/2016 03:22PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: MechaBits KraftWerk'r October 20, 2016 05:59PM |

Registered: 8 years ago Posts: 1,671 |

Yo D' fix me up some blingin gold teeth....are they good clients  the rapper video doesn't really match those lyrics...

the rapper video doesn't really match those lyrics...

was expecting something like these

[www.youtube.com]

or

[www.youtube.com]

the reason I brought these muso's into the thread was mainly because of the robots, replicants, 8bit op's & raster graphics,tron, synths & electronics, UV & neon lightshows, etc

6mm bearings & feeder came today, still waiting on another controller, so time to start on a redesign of the carriage and other arm options.

the rapper video doesn't really match those lyrics...

the rapper video doesn't really match those lyrics...was expecting something like these

[www.youtube.com]

or

[www.youtube.com]

the reason I brought these muso's into the thread was mainly because of the robots, replicants, 8bit op's & raster graphics,tron, synths & electronics, UV & neon lightshows, etc

6mm bearings & feeder came today, still waiting on another controller, so time to start on a redesign of the carriage and other arm options.

|

Re: MechaBits KraftWerk'r October 22, 2016 02:14PM |

Registered: 8 years ago Posts: 1,671 |

The best RepRap video i've ever seen

from Sexy Cyborg, damn these robots are getting realistic...where can I order one.

Though might have to subscribe in case there are better ones.

[youtu.be]

I can DL the Skin right now but havent enough silicone to complete the build

[www.thingiverse.com]

Edited 4 time(s). Last edit at 10/22/2016 02:36PM by MechaBits.

from Sexy Cyborg, damn these robots are getting realistic...where can I order one.

Though might have to subscribe in case there are better ones.

[youtu.be]

I can DL the Skin right now but havent enough silicone to complete the build

[www.thingiverse.com]

Edited 4 time(s). Last edit at 10/22/2016 02:36PM by MechaBits.

|

Re: MechaBits KraftWerk'r October 22, 2016 04:34PM |

Registered: 11 years ago Posts: 5,780 |

Careful, you're getting into Trump territory here...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: MechaBits KraftWerk'r October 22, 2016 05:04PM |

Registered: 8 years ago Posts: 1,671 |

Lol never in A Million years, it's just some harmless misogynistic objectifying of women locker room banter.

It's fun watching women newscasters say 'no, we never talk about matter's of mens endowment when it's a girls night out'

No we never marry a dweeb with money and get pregnant to someone else with better genes.

PC is going too far.

Edited 1 time(s). Last edit at 10/23/2016 06:31PM by MechaBits.

It's fun watching women newscasters say 'no, we never talk about matter's of mens endowment when it's a girls night out'

No we never marry a dweeb with money and get pregnant to someone else with better genes.

PC is going too far.

Edited 1 time(s). Last edit at 10/23/2016 06:31PM by MechaBits.

|

Re: MechaBits KraftWerk'r October 28, 2016 10:17PM |

Registered: 8 years ago Posts: 1,671 |

Blink and you'll miss it, god damn sexy cyborg, guess who needs a new arm...yeah the Kraftwerkr Robot

Work has begun on a new arm for the Kraftwerkr with parts mentioned above, I've run out of silver so will be reprinting in black, wish I had some luminescent filament.

time to try & get more silver, dont think the arm will look good in black.

The Kraftwerk visual show has lots of road sign's in it so thought I would make the carriage into the arrow..

hopefully the reprint will be better.

Edited 2 time(s). Last edit at 10/29/2016 04:26AM by MechaBits.

|

Re: MechaBits KraftWerk'r October 29, 2016 09:27AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: MechaBits KraftWerk'r October 29, 2016 11:31PM |

Registered: 8 years ago Posts: 1,671 |

Yes ICANN ... is it any wonder, pumped into brain on a daily basis for a few years...something is bound to stick, lets hope she has access to plenty of rope...so we managed TRump & Clinton in a thread about robotic puppets, cool.

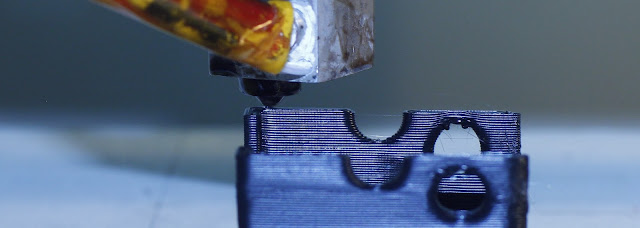

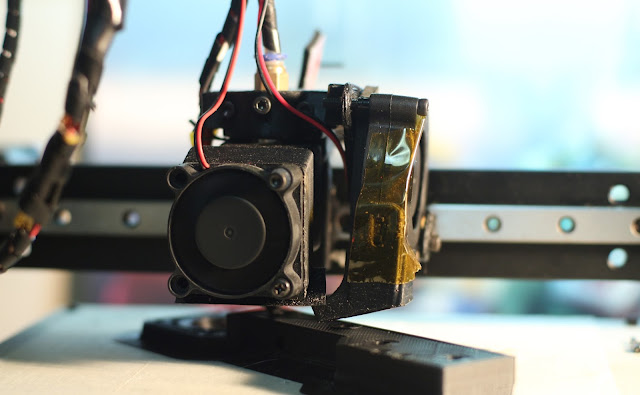

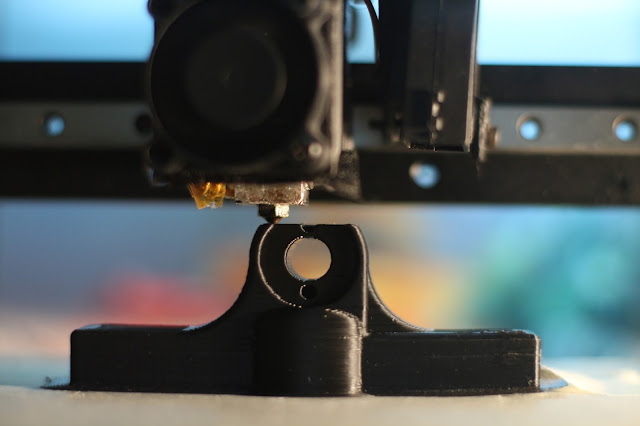

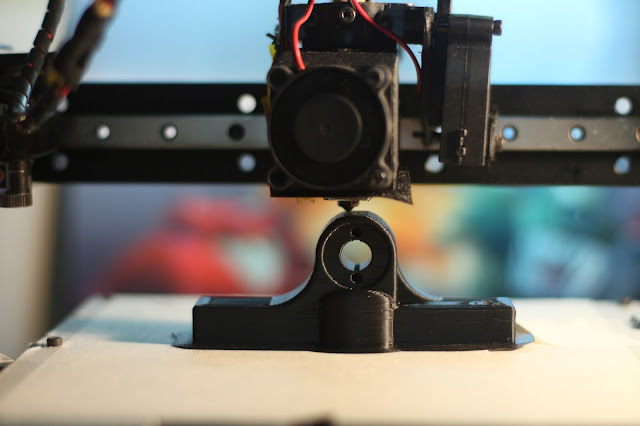

Reprinted the carriage as the other wasn't true, I've added a new base for my Z so still lining things up,

Thought I would do 0.2mm on layers with the .5 nozzle, for the first time, and changing back to black,

and I think it has improved on the warping, against expectations, I was thinking lower layer heights = more time to warp more heat on part, but I think the reduction in volume of plastic has allowed the part to cool quicker more evenly.

Edited 1 time(s). Last edit at 10/30/2016 02:07AM by MechaBits.

Reprinted the carriage as the other wasn't true, I've added a new base for my Z so still lining things up,

Thought I would do 0.2mm on layers with the .5 nozzle, for the first time, and changing back to black,

and I think it has improved on the warping, against expectations, I was thinking lower layer heights = more time to warp more heat on part, but I think the reduction in volume of plastic has allowed the part to cool quicker more evenly.

Edited 1 time(s). Last edit at 10/30/2016 02:07AM by MechaBits.

|

Re: MechaBits KraftWerk'r November 04, 2016 08:28AM |

Registered: 8 years ago Posts: 1,671 |

Bought a light panel 600x600 48w led, £20, always wanted a light table for photography looking at slides & neg's, now its either but will use it more for lighting, great for the sides of the Cube, though 300x300 are probably better for that.

[io-matter.blogspot.co.uk]

|

Re: MechaBits KraftWerk'r November 07, 2016 04:57AM |

Registered: 8 years ago Posts: 1,671 |

Funny how this other company ended up in a similar place to this thread

with the arrow logo

Another arm in the making, hoping to keep it modular, wondering where it will be used best,

The one on the right is the new one, designed for the Cube (x) attaches via clamping to groove on backing plate,

but I'm also considering it to replace the arm on the first printer, so designing ends for different applications,

though I've also made a carriage for it that also runs on the grooves...maybe I dont need the linear rail on this,

the reason I bought the piece was to try that idea out.

Decisions Decisions... the linear rail is going to be hard to beat, but had to try, preliminary tests seem ok, little deviation, but not a smooth, V goove rubber/delrin wheels might be better but the cost mounts up.

Edited 4 time(s). Last edit at 11/07/2016 08:56PM by MechaBits.

with the arrow logo

Another arm in the making, hoping to keep it modular, wondering where it will be used best,

The one on the right is the new one, designed for the Cube (x) attaches via clamping to groove on backing plate,

but I'm also considering it to replace the arm on the first printer, so designing ends for different applications,

though I've also made a carriage for it that also runs on the grooves...maybe I dont need the linear rail on this,

the reason I bought the piece was to try that idea out.

Decisions Decisions... the linear rail is going to be hard to beat, but had to try, preliminary tests seem ok, little deviation, but not a smooth, V goove rubber/delrin wheels might be better but the cost mounts up.

Edited 4 time(s). Last edit at 11/07/2016 08:56PM by MechaBits.

|

Re: MechaBits KraftWerk'r November 09, 2016 06:32AM |

Registered: 8 years ago Posts: 1,671 |

Woke up to find Trump is the landslide winner....God Bless America ...lol Pollsters need to find a new profession.

Put the new arm together, still need to design the ideal carriage, but while thinkiing about what that should be, I couldnt help putting together something that works from my bag of Mechabits, a box of functional parts, which seems to be getting bigger(perhaps not as functional as I wanted), so I used a piece printed to attach to the carriage, and some perspex parts from my very first experiments with perspex, which seems ideal for the job, and possibly better than any 3d part I could design/print, its the same piece i designed to drive my other x carriage, though in this config maybe more prone to snapping...I'd like the carriage in one piece but its tricky and might be better with multiple parts that come together.

So now I have this arm I'd like it to be for the cube, but I'm thinking about putting it on the first printer

would be interesting to see what the improvement would be, last shot is with current arm...

would rather print more stuff first so as not to mess things up while its running fine.

I can recover lots of parts and have a much simpler look to the machine...but I'm attached to the original design,

a shame to tear the arm down, in the name of progress.

Edited 2 time(s). Last edit at 11/09/2016 12:11PM by MechaBits.

Put the new arm together, still need to design the ideal carriage, but while thinkiing about what that should be, I couldnt help putting together something that works from my bag of Mechabits, a box of functional parts, which seems to be getting bigger(perhaps not as functional as I wanted), so I used a piece printed to attach to the carriage, and some perspex parts from my very first experiments with perspex, which seems ideal for the job, and possibly better than any 3d part I could design/print, its the same piece i designed to drive my other x carriage, though in this config maybe more prone to snapping...I'd like the carriage in one piece but its tricky and might be better with multiple parts that come together.

So now I have this arm I'd like it to be for the cube, but I'm thinking about putting it on the first printer

would be interesting to see what the improvement would be, last shot is with current arm...

would rather print more stuff first so as not to mess things up while its running fine.

I can recover lots of parts and have a much simpler look to the machine...but I'm attached to the original design,

a shame to tear the arm down, in the name of progress.

Edited 2 time(s). Last edit at 11/09/2016 12:11PM by MechaBits.

|

Re: MechaBits KraftWerk'r November 09, 2016 10:53AM |

Registered: 11 years ago Posts: 5,780 |

America (or should I say Amerika?) has lost its collective mind. Godwin's law is undeniable/irrevocable - now I know what sane people in Germany felt like in the 30s.

New project: dental license in Canada...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

New project: dental license in Canada...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: MechaBits KraftWerk'r November 09, 2016 11:00AM |

Registered: 8 years ago Posts: 1,671 |

Someone used to tell me as far back as the 70/80's america was the A hole of the world...now its mouthpiece is Trump (or Fart in the UK)

Funny how people fear his finger on the button, but there where many things Obama couldnt do without others, I doubt people will let him anywhere near the big red switch.

Though I just heard Hillary defend freedom of WarShip...Freudian slip...though it also sounded like whoreship....or could have been freedom from horsesh#t I cant tell...need a new battery for the hearing aid.

our best days are ahead of us....duh...people would be in a mess if they wheren't as there's no going back

though if things end up like the 30's maybe its a form of time travel.

Edited 5 time(s). Last edit at 11/09/2016 11:54AM by MechaBits.

Funny how people fear his finger on the button, but there where many things Obama couldnt do without others, I doubt people will let him anywhere near the big red switch.

Though I just heard Hillary defend freedom of WarShip...Freudian slip...though it also sounded like whoreship....or could have been freedom from horsesh#t I cant tell...need a new battery for the hearing aid.

our best days are ahead of us....duh...people would be in a mess if they wheren't as there's no going back

though if things end up like the 30's maybe its a form of time travel.

Edited 5 time(s). Last edit at 11/09/2016 11:54AM by MechaBits.

|

Re: MechaBits KraftWerk'r November 12, 2016 10:43AM |

Registered: 8 years ago Posts: 1,671 |

The Resemblance is uncanny....

So much for cobbling together a carriage out of perspex, even though it worked, progress never sleeps, I got stuck into a printed solution, though not one piece, keep it modular...I have 2 carts on the rail, if I remove one I might loose my balls...If I leave it on, more support...Initially wanted 2 halves of carriage to clamp together around hotend, but veered off in another direction, Sensor & laser mount on one cart(laser's just for show, but maybe help with alignment), hotend on the other(which can be rearranged for dual). I wanted a bolt to join the 2 carts...but warping messed alignment & hole dim's, so I added a magnet(finally) hope it wont magnetize my balls.... now the idea is I could leave the carriage with laser down one end when not in use.....but anytime the other carriage gets close...they would be hitched..so wonder if there are any tiny electomagnets? so it could be disconnected at will.

So much for cobbling together a carriage out of perspex, even though it worked, progress never sleeps, I got stuck into a printed solution, though not one piece, keep it modular...I have 2 carts on the rail, if I remove one I might loose my balls...If I leave it on, more support...Initially wanted 2 halves of carriage to clamp together around hotend, but veered off in another direction, Sensor & laser mount on one cart(laser's just for show, but maybe help with alignment), hotend on the other(which can be rearranged for dual). I wanted a bolt to join the 2 carts...but warping messed alignment & hole dim's, so I added a magnet(finally) hope it wont magnetize my balls.... now the idea is I could leave the carriage with laser down one end when not in use.....but anytime the other carriage gets close...they would be hitched..so wonder if there are any tiny electomagnets? so it could be disconnected at will.

|

Re: MechaBits KraftWerk'r November 13, 2016 08:36PM |

Registered: 8 years ago Posts: 1,671 |

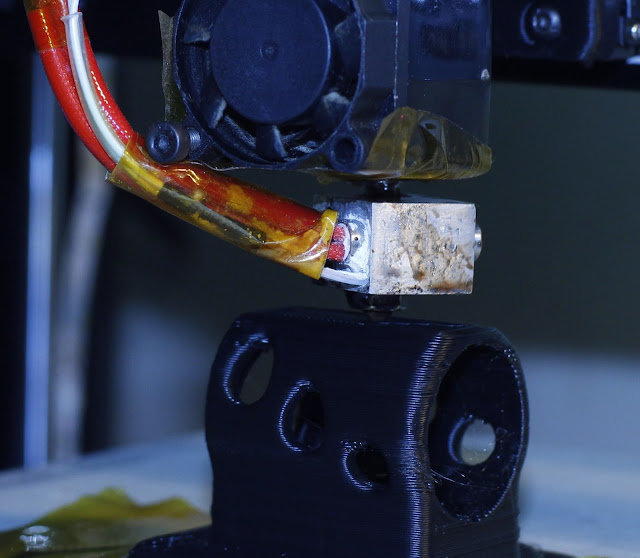

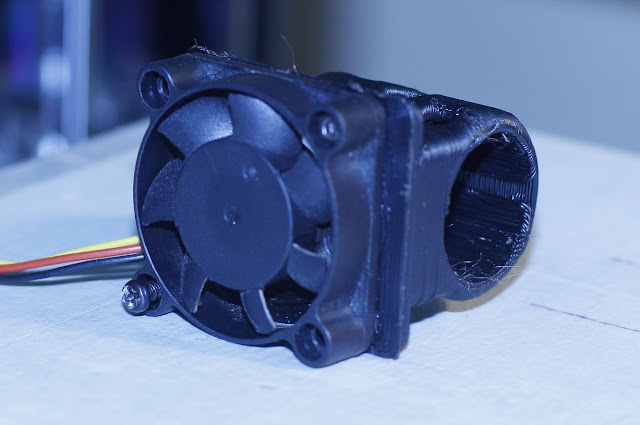

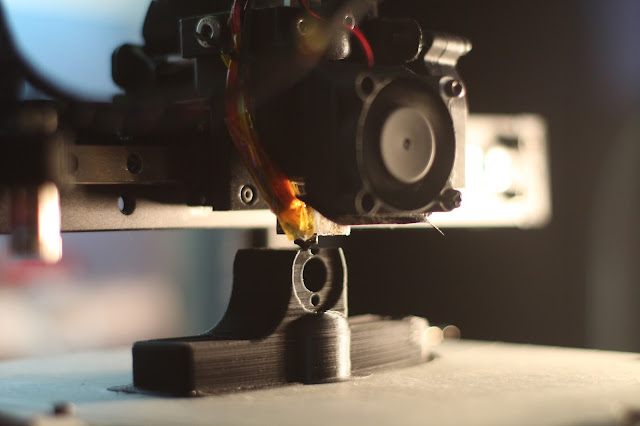

While printing parts for the new arm, one of which was a 40mm fan shroud, the gremlins where messing with the hotend temp and it wasn't keeping temp' thought I might have bunged it up in the process, so had to dismantle to investigate, this was the perfect time to attach the new arm and test it out, so on it went, checked all the wires to hotend dismantled and reassembled. Time to solve the mystery of the non printing fan shroud..tempted to just print a test cube, I decided to skip that as first print on new arm, and go straight to the turin shroud...a tricky object as it has quite thin walls, thinner than I've tried before, no layer fan on at the moment, so interesting to see what happens.

While adding the new arm I also dropped the bed height, the laser was used to align things, the last laser failed and aligning without it a real pain, the new arm has more clearance too, the arm looks like its floating in mid air, reminding me of the levetations of old, so I gained about 200mm on my Z, the first setup was not ideal, but at first all I wanted was low parts. So hotend held temp, speed was up, & print completed in 1hr 30min, here are the results, the need for a direct or more precise filament feeder is something for the future, though for a first print with new setup, the shroud came out fine, cant wait to add it...but its designed for the V6 hotend not the V5 so will be leaving that for another day. why the hotend wasnt holding temp will remain a mystery.

Edited 4 time(s). Last edit at 11/13/2016 10:21PM by MechaBits.

|

Re: MechaBits KraftWerk'r November 16, 2016 12:20PM |

Registered: 8 years ago Posts: 1,671 |

Printed another fan shroud for the V5, so my printer has a new face,

not a yoda head but the force is strong with this one

Edited 1 time(s). Last edit at 11/16/2016 12:27PM by MechaBits.

|

Re: MechaBits KraftWerk'r November 21, 2016 10:00PM |

Registered: 8 years ago Posts: 1,671 |

Slight deviation from the Kraftwerkr printer, Redesigned the carriage to bring hotend closer to rail and a little higher, was going to add space for extra hotend but will probably do another mount, was going to add a few extra details to guide cables, flashing lights, endstops, direct drive(though can design another piece that uses the bolts for support), but in rush to print you forget to add everything, I just left a few holes on top for another piece. Previous one piece carriage working fine and lighter than this, but while things are running fine thought it a good idea to print extra's, layer fan really makes all the difference.

|

Re: MechaBits KraftWerk'r December 04, 2016 04:12PM |

Registered: 8 years ago Posts: 1,671 |

Wanted more rails, but picked up other bits in the deal, so this one is now taking center stage...so many permutations,

I thought I might use the triangle slabs as the cantilevers for the cube or support for large bed, but at 10mm thick they weigh a bit...would need the nema 23 that came with this to lift it, so maybe maybe not. Meanwhile i'm liking this config(even better if the scara was a working prototype), I almost have the slim bed design I wanted, though if I put the bed from the Kraftwerkr on the dual rails I could have X/Y table(though would be a great z too)....so I might as well tear the rest of that design down, and add the parts to this build. So the frame for the Z came with 2 pacific scientific motors a 23 at top and another at bottom with 2 seperate short leadscrews, antibacklash nuts & right angled actuator link( I was tempted to have Z move in 2 directions at once, lower bed & raise head at same time, so I could use these leadscrews, but then I would probably be best moving the dual rails back to the Z), one motor has slightly larger flange than a 17 but I think the motor is a decent 17, wondering if I should use it 1.39A 57w 65v so wonder if it was given 12v would it work?

the nema 23 is a beast...maybe one day i'll use it, they each came with a controller, but I probably will never figure out if they can be used, maybe they would be better in someone else's hands.

Plenty of permutations to play with, should keep me busy for a while.

|

Re: MechaBits KraftWerk'r December 05, 2016 01:54PM |

Registered: 8 years ago Posts: 1,671 |

Bottom bracket done, top in the worx, but enough of 3D printing for today.

Edited 1 time(s). Last edit at 12/05/2016 01:55PM by MechaBits.

Edited 1 time(s). Last edit at 12/05/2016 01:55PM by MechaBits.

|

Re: MechaBits KraftWerk'r December 07, 2016 10:22AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: MechaBits KraftWerk'r December 09, 2016 07:34PM |

Registered: 8 years ago Posts: 1,671 |

Sorry, only registered users may post in this forum.