Stuck

Posted by Dark Alchemist

|

Re: Stuck March 23, 2017 02:56AM |

Registered: 11 years ago Posts: 1,277 |

I am floating between each and since I have to print up parts no matter what and I have PTSD with the amount of rods I had to go through plus I am just not convinced about the carbon rod because I know they flex when the belt is tensioned no matter what. I really like the idea as it is sort of like the Core XY where no rods needed just screws, pulleys, and bearings and long belts.Quote

o_lampe

I'm afraid even with a carbon rod, you'll need one flex coupling.

But it seems we are back to the belt idea?

I was looking at metal lathes and 700-800 dollars would get me one to turn down what I need but I barely ever need a lathe though I would never turn one down either.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

I would use metal motor mounts at each corner...they can be adapted to hold 8 mm bearings, then everythings stiff, and same height.

Edited 2 time(s). Last edit at 03/23/2017 06:20AM by MechaBits.

Edited 2 time(s). Last edit at 03/23/2017 06:20AM by MechaBits.

Forget about the lathe! You'd never improve rod roundness that way. The chisel will bend the rod before taking off material.

With a carbon rod, a short piece of steel rod and one flex coupling you can use all four bearing holders without binding. You wouldn't even need another bearing block in the middle.

With a carbon rod, a short piece of steel rod and one flex coupling you can use all four bearing holders without binding. You wouldn't even need another bearing block in the middle.

|

Re: Stuck March 31, 2017 02:10AM |

Registered: 11 years ago Posts: 1,277 |

I haven't had time to design a belt system yet but I sent a message to an ebay seller for 5mm/3mm 1m long carbon rods and I asked how straight and true are they as I need to use them as an axle type system so I need something of quality and, of course, no response. Normally when a seller (this was a seller in the USA) doesn't respond back it means they are selling junk or at least that has been my experience.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Stuck April 03, 2017 10:11AM |

Registered: 11 years ago Posts: 1,277 |

I had some time yesterday and redesigned my X ends and next day I get free I will tackle the Y ends as well as the wheel pieces but I was looking and I could change out my 20t for 32t (not cheap) and it would give me 200 steps per mm so double my resolution for half the speed but two questions would be is that sort of 5 micron resolution needed and what negatives would there be in doing this?

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

How did you go with the design, I never did get around to CADing up a design (work got crazy) but if you still need ideas I'm happy to give it a go.

Also MechaBits has a post in the general about turning his printer into a rail gun, If you look at one of the last pics he posts it shows a pulley to shaft couple design that you might find useful

Edited 1 time(s). Last edit at 04/10/2017 12:29AM by scottybfg.

Also MechaBits has a post in the general about turning his printer into a rail gun, If you look at one of the last pics he posts it shows a pulley to shaft couple design that you might find useful

Edited 1 time(s). Last edit at 04/10/2017 12:29AM by scottybfg.

|

Re: Stuck April 10, 2017 03:09PM |

Registered: 11 years ago Posts: 1,277 |

That is pretty neat I must say.

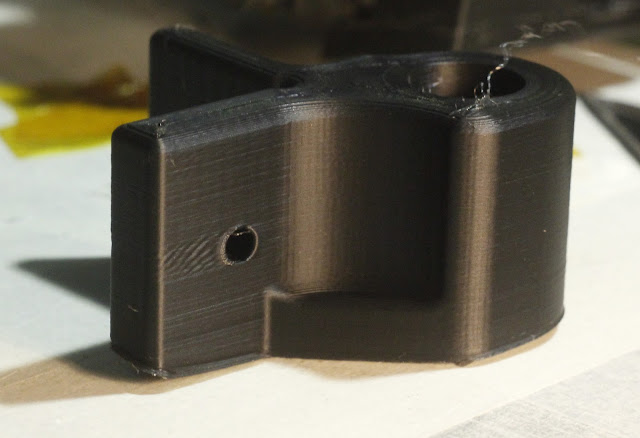

I found some time this past weekend to do them but I forgot about the bearings (doh) so had only enough time to do one set (because each side is a mirror image you must make two). Basically each diagonal corner is the same. Will this design work? I am not sure but I am doing the belt design since I can't get any seller on ebay to respond to tell me if what they are selling is straight and true. By their lack of responding (all six of them) I must take that to mean they are selling junk for my needed purpose so I am going with the belt option over the long axle rod idea.

Where this will get fun is when designing the wheel holders because you have to have one inside and one outside as grippers. I am also unsure how long this continuous loop belt will need to be and that part does put me off since I have no way to tension it (I can't think of a way to do it). The belts for the wheel parts doesn't need to be so all is fine there.

As far as the tensioning goes I believe I will just pull the motor out to take up any slack that happens. I will use four M5x50mm bolts and two 625zz bearings per corner with two pulleys on each side with the loop belt (2 16t and two 20t) and only 1 on each side on the opposite side (1 20t on each side). This will give me 1.25 but to be honest if I could manage 32t I would but they are just too big for the very limited space I am dealing with on each corner.

Edited 1 time(s). Last edit at 04/10/2017 03:15PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

I found some time this past weekend to do them but I forgot about the bearings (doh) so had only enough time to do one set (because each side is a mirror image you must make two). Basically each diagonal corner is the same. Will this design work? I am not sure but I am doing the belt design since I can't get any seller on ebay to respond to tell me if what they are selling is straight and true. By their lack of responding (all six of them) I must take that to mean they are selling junk for my needed purpose so I am going with the belt option over the long axle rod idea.

Where this will get fun is when designing the wheel holders because you have to have one inside and one outside as grippers. I am also unsure how long this continuous loop belt will need to be and that part does put me off since I have no way to tension it (I can't think of a way to do it). The belts for the wheel parts doesn't need to be so all is fine there.

As far as the tensioning goes I believe I will just pull the motor out to take up any slack that happens. I will use four M5x50mm bolts and two 625zz bearings per corner with two pulleys on each side with the loop belt (2 16t and two 20t) and only 1 on each side on the opposite side (1 20t on each side). This will give me 1.25 but to be honest if I could manage 32t I would but they are just too big for the very limited space I am dealing with on each corner.

Edited 1 time(s). Last edit at 04/10/2017 03:15PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Stuck April 17, 2017 06:42AM |

Registered: 11 years ago Posts: 1,277 |

I had more time this weekend to work on it and it appears I will need a 1080mm (1077-1080mm) closed loop GT2 belt but where would I buy that from? At 1080mm it already is stretching the limit and to be honest a 1078 looks (in cad) to be perfect.

Any ideas on the belt for this?

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

Any ideas on the belt for this?

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

Sorry, only registered users may post in this forum.