Synchronicity in interesting ideas

Posted by Lykle

|

Synchronicity in interesting ideas February 09, 2017 08:06AM |

Registered: 8 years ago Posts: 312 |

Every now and then you get some interesting ideas pop up at the same time.

For instance: A Nimble customer Bob, asked me "If we came up with a cam system for hold downs instead of 2 bolts, that would be fantastic."

I was mulling this over for a day or 2 and came up with the solution mentioned in another post.

Went to the Duet3d forum to check the discussions there and lo and behold, Deckingman has come up with the same solution, but for a slightly different problem.

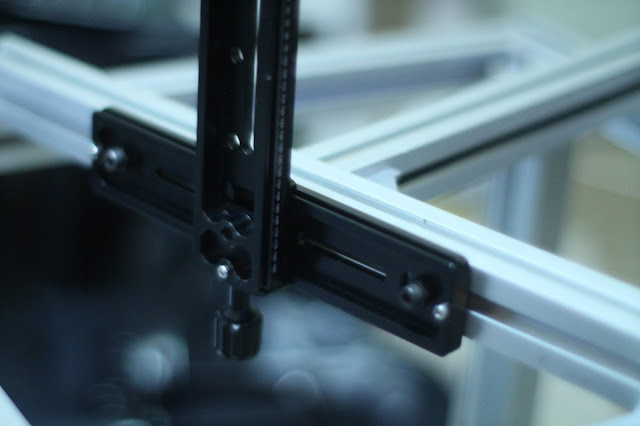

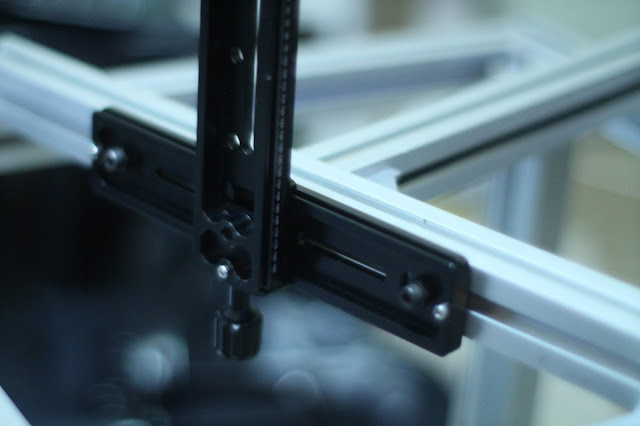

Here are the images he shared. He obviously is a lot further in this than I am. (is there an emoji for tipping the hat?)

Both ideas use a prism sides to ensure positional accuracy for the hot end. Deckingman sets his vertical so the hot end can slide up and down, mine are horizontal but the basic idea is the same.

The idea is that you have a "french cleat" system.to position the part that clamps the hot end. The wedges and the hot end sticking up, position the whole accurately and the wedged clamp locks it into place.

Is this something you could use? What would be the problems with it? The design is pretty basic but I will post the design files on Thingiverse anyway.

I would like a more "cartridge" driven approach to print heads. This is just one way of getting there, but a valid one I think.

Any comments?

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

For instance: A Nimble customer Bob, asked me "If we came up with a cam system for hold downs instead of 2 bolts, that would be fantastic."

I was mulling this over for a day or 2 and came up with the solution mentioned in another post.

Went to the Duet3d forum to check the discussions there and lo and behold, Deckingman has come up with the same solution, but for a slightly different problem.

Here are the images he shared. He obviously is a lot further in this than I am. (is there an emoji for tipping the hat?)

Both ideas use a prism sides to ensure positional accuracy for the hot end. Deckingman sets his vertical so the hot end can slide up and down, mine are horizontal but the basic idea is the same.

The idea is that you have a "french cleat" system.to position the part that clamps the hot end. The wedges and the hot end sticking up, position the whole accurately and the wedged clamp locks it into place.

Is this something you could use? What would be the problems with it? The design is pretty basic but I will post the design files on Thingiverse anyway.

I would like a more "cartridge" driven approach to print heads. This is just one way of getting there, but a valid one I think.

Any comments?

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

|

Re: Synchronicity in interesting ideas February 09, 2017 08:33AM |

Registered: 12 years ago Posts: 2,470 |

I use a slot based approach to quickly exchange complete printheads for the purpose

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Synchronicity in interesting ideas February 09, 2017 10:09AM |

Registered: 8 years ago Posts: 312 |

|

Re: Synchronicity in interesting ideas February 09, 2017 10:15AM |

Registered: 9 years ago Posts: 425 |

Take a look at a camera tripod.

Dont say i dont give you anything Lykle

Edited 1 time(s). Last edit at 02/10/2017 05:58AM by Mutley3D.

Flex3Drive.com

Dont say i dont give you anything Lykle

Edited 1 time(s). Last edit at 02/10/2017 05:58AM by Mutley3D.

Flex3Drive.com

|

Re: Synchronicity in interesting ideas February 09, 2017 11:19AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Synchronicity in interesting ideas February 09, 2017 11:48AM |

Registered: 12 years ago Posts: 2,470 |

There is no lock, it is a tight fit and all acceleration forces work perpendicular to the slot.Quote

Lykle

Ah yes, I see.

How does it lock into place?

And in the background is a different print head?

There is a second extruder, but it is not in the image. Check my website for more info.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Synchronicity in interesting ideas February 09, 2017 12:38PM |

Registered: 7 years ago Posts: 249 |

I like your concept (saw it on the 3d printers/builders FB page).

One observation, doesn't look like there's adequate wedge to cam clearance to remove the hot end. A larger cam may be required.

Second, does not address various hot end dimensions, diameters and neck lengths.

Last, leaves connectivity and wiring routing up in the air for the users to figure out .

I'm in favor of the Toranado approach, with a cartridge. Requires more parts and engineering to accommodate more hot end mfgs, however does incorporate wiring.

For reference, here's a Prometheus cartridge I made for the Toranado:

[www.thingiverse.com]

After some more refinement, your solution can be a very quick and simple hot swap.

Oh yea, what flexible drive do you recommend for the nimble?

One observation, doesn't look like there's adequate wedge to cam clearance to remove the hot end. A larger cam may be required.

Second, does not address various hot end dimensions, diameters and neck lengths.

Last, leaves connectivity and wiring routing up in the air for the users to figure out .

I'm in favor of the Toranado approach, with a cartridge. Requires more parts and engineering to accommodate more hot end mfgs, however does incorporate wiring.

For reference, here's a Prometheus cartridge I made for the Toranado:

[www.thingiverse.com]

After some more refinement, your solution can be a very quick and simple hot swap.

Oh yea, what flexible drive do you recommend for the nimble?

|

Re: Synchronicity in interesting ideas February 09, 2017 01:40PM |

Registered: 9 years ago Posts: 1,873 |

Quote

prot0typ1cal

One observation, doesn't look like there's adequate wedge to cam clearance to remove the hot end. A larger cam may be required.

Isn't that why there's a flat on the side of the cam?

Looks great to me. I made a metal dovetail recently that I'm hoping to use for fine vertical adjustment for leveling dual extruders, but it doesn't have any quick release capability. It's also a bit on the heavy side, so I'm not completely committed to using it.

|

Re: Synchronicity in interesting ideas February 09, 2017 03:14PM |

Registered: 7 years ago Posts: 249 |

Quote

JamesK

Quote

prot0typ1cal

One observation, doesn't look like there's adequate wedge to cam clearance to remove the hot end. A larger cam may be required.

Isn't that why there's a flat on the side of the cam?

Color me wrong, looks like the grey plate needs to slide before it can drop is all... which would mean additional gap needed between the flat and wedge.

|

Re: Synchronicity in interesting ideas February 09, 2017 07:12PM |

Registered: 8 years ago Posts: 1,671 |

who was it said Synchronicity the sincerest form of flattery...thats right no one

Cantilever with Dovetails, but I can probably do away with this arrangement 2 shorter arca's at the ends to attach to rails

DoveTails are cool..Standardized Plastic Picatinny Rails would be good.

for £1.69 one of these to hold a hotend, (more weight though)

Is the hole in the cam off center? looks like it is a little.

Edited 10 time(s). Last edit at 02/10/2017 07:21PM by MechaBits.

Cantilever with Dovetails, but I can probably do away with this arrangement 2 shorter arca's at the ends to attach to rails

DoveTails are cool..Standardized Plastic Picatinny Rails would be good.

for £1.69 one of these to hold a hotend, (more weight though)

Is the hole in the cam off center? looks like it is a little.

Edited 10 time(s). Last edit at 02/10/2017 07:21PM by MechaBits.

|

Re: Synchronicity in interesting ideas February 11, 2017 01:40PM |

Registered: 8 years ago Posts: 312 |

Check our site.Quote

prot0typ1cal

Oh yea, what flexible drive do you recommend for the nimble?

" is the green locking part excentric?" Yes it is. And it has a flat side because you rotate it clockwise and then lift out the plate.

"Take a look at a camera tripod. " Yes that is exactly where I got the idea, as mentioned in the other post.

For sure it is just a simple thought experiment right now, but I have printed out a few pieces and it does seem to work. (why wouldn't it?)

And indeed it does nothing for cables, height adjustment etc. Was not intended to. Adding a plug for the wires is simple, but height is an interesting one.

As for space enough to open.

Yes MechaBits, the hole in the Cam is off center.

I was thinking of adding a torsion spring to keep the cam closed, not sure if it is needed. Simple add.

Edited 2 time(s). Last edit at 02/11/2017 01:44PM by Lykle.

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

|

Re: Synchronicity in interesting ideas February 11, 2017 02:06PM |

Registered: 9 years ago Posts: 1,873 |

Quote

Lykle

I was thinking of adding a torsion spring to keep the cam closed, not sure if it is needed. Simple add.

Typically not needed, just make sure that the off-centre axis is placed so that the closed position is just past the maximum diameter. Then you get over-locking such that extra force has to be applied to open the cam.

|

Re: Synchronicity in interesting ideas February 12, 2017 01:57AM |

Registered: 8 years ago Posts: 312 |

Sorry, only registered users may post in this forum.